they were right to trust us !

OPTIMIZATION OF ENERGY CONSUMPTION

Stop the thousands of euros wasted to burn, heat, cool, air-condition.. The intervention of ROCHE TECHNOLOGIES has enabled many customers to halve their consumption of electricity, gas, or fuel. Among them, several industrialists were able at the same time to double their production capacity. The Return on Investment corresponding to the implementation of our recommendations is generally obtained over a period of less than 1 year.

Stop the thousands of euros wasted to burn, heat, cool, air-condition.. The intervention of ROCHE TECHNOLOGIES has enabled many customers to halve their consumption of electricity, gas, or fuel. Among them, several industrialists were able at the same time to double their production capacity. The Return on Investment corresponding to the implementation of our recommendations is generally obtained over a period of less than 1 year.

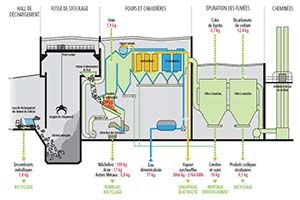

COMBUSTION and FLUE GAS TREATMENT

have been the core business of ROCHE TECHNOLOGIES since its inception.

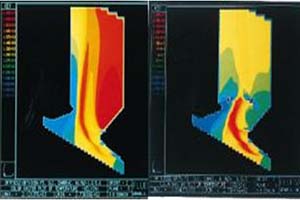

In thermal processes such as incineration, sludge, waste, biomass, biogas or syngas, we have adapted furnaces and boilers to keep their waste load or heat load despite the variation in calorific value due to selective sorting and climatic conditions. At the same time, our interventions reduce both the emission of nitrogen oxides and carbon monoxide, as well as reduce clutches and fouling in furnaces and boilers. Our specific processes favor the absence of use of expensive reagents and more or less dangerous properties. The implementation of our recommendations results in results far exceeding legal standards.

have been the core business of ROCHE TECHNOLOGIES since its inception.

In thermal processes such as incineration, sludge, waste, biomass, biogas or syngas, we have adapted furnaces and boilers to keep their waste load or heat load despite the variation in calorific value due to selective sorting and climatic conditions. At the same time, our interventions reduce both the emission of nitrogen oxides and carbon monoxide, as well as reduce clutches and fouling in furnaces and boilers. Our specific processes favor the absence of use of expensive reagents and more or less dangerous properties. The implementation of our recommendations results in results far exceeding legal standards.

STEP PIERRE BÉNITE GRAND LYON – FR

2015-2016

Rebuilding the reagent storage in the UF7 building.

Design and maintenance studies. Supply of process equipment.

Coordination of the site. MSI.

Incineration of sludge from STEP

Design and maintenance studies. Supply of process equipment.

Coordination of the site. MSI.

Incineration of sludge from STEP

SHOPPING CENTER SAINT MARTIAL LIMOGES-FR

DEPUIS 2005

2003-2009

Balance sheet in light of the energy optimization

Operation optimisation

Aid at the extension of shopping center (air conditioning)

2010-2013

Renovation of cooling towers and energy optimization (energy savings of 20%)

2015

Study of the replacement of gas boilers.

Balance sheet in light of the energy optimization

Operation optimisation

Aid at the extension of shopping center (air conditioning)

2010-2013

Renovation of cooling towers and energy optimization (energy savings of 20%)

2015

Study of the replacement of gas boilers.

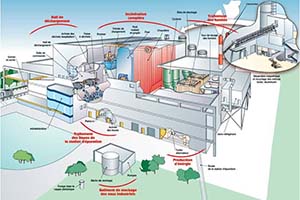

ENERGY RECOVERY CENTER LYON SUD-FR

2010-2014

2010-2012

Flue gas treatment maintenance and optimization of three incineration waste lines (scrubber, catalyst, heat exchanger)

2013 - 2014

Expertise of dysfunctions.

Repair of GEA FLUCOREX heat exchangers.

Replacement of valves and renovation of scrubbers in SVR.

Flue gas treatment maintenance and optimization of three incineration waste lines (scrubber, catalyst, heat exchanger)

2013 - 2014

Expertise of dysfunctions.

Repair of GEA FLUCOREX heat exchangers.

Replacement of valves and renovation of scrubbers in SVR.

ECOTUBE SYSTEM FOR FRANCE

DEPUIS 2004

2005: Coordination for achieving DeNOx compliance for Lons-le-Saunier, Bessieres ECONOTRE and for Pontmain Line 2

2006: Pontmain, Line 2 Energy optimization Econotre

2006: Injection of sludge Valezan-FR

2007: MSVI Montargis-FR

2008: Saint Ouen CPCU-FR

2008: Besançon MSWI - FR

2009: Saint Ouen CPCU -FR

2011: SIDEC, The Gol Island-FR

2006: Pontmain, Line 2 Energy optimization Econotre

2006: Injection of sludge Valezan-FR

2007: MSVI Montargis-FR

2008: Saint Ouen CPCU-FR

2008: Besançon MSWI - FR

2009: Saint Ouen CPCU -FR

2011: SIDEC, The Gol Island-FR

AVR ROTTERDAM-NL

2011

Flue gas treatment maintenance and optimization of three incineration waste lines (scrubber, catalyst, heat exchanger)

INARIZ - LAMBALLE-FR

2010

Energy Optimization: process analysis and project

VIP LYON-FR

DEPUIS 2003

Expertise, technical advices, implementation of solutions: air conditioning, raising, infiltration, etc..

Malfunctions expertise, testing, suggestions for improvement and site supervision

Malfunctions expertise, testing, suggestions for improvement and site supervision

MSWI METZ-FR

2008

Security survey HCl and Dioxins / Furans

Site survey and documents analysis

Analysis of the operation: combustion, flue gas treatment, operating

Proposals for improvement

Site survey and documents analysis

Analysis of the operation: combustion, flue gas treatment, operating

Proposals for improvement

MSWI SENS-FR

2007

Optimization of the energy of the recovery plant coupled to the district heating network

Proposal of operating improvement

Study of electrical recovery

Proposal of operating improvement

Study of electrical recovery

MSWI VITRE-FR

2007-2010

2007-2009:

Combustion stabilisation with high calorific values and limitation of boiler fouling.

Site Expertise, tests, implementation of BrumiDeNOx system, reduction of fouling of boilers, capacity enhancement in case of household waste with high calorific value.

DeNOx efficiency, NOx <200 mg/Nm3 without chemical additives.

2010:

Assistance for the implementation and commissioning of the heating network and energy recovery in the plant

Combustion stabilisation with high calorific values and limitation of boiler fouling.

Site Expertise, tests, implementation of BrumiDeNOx system, reduction of fouling of boilers, capacity enhancement in case of household waste with high calorific value.

DeNOx efficiency, NOx <200 mg/Nm3 without chemical additives.

2010:

Assistance for the implementation and commissioning of the heating network and energy recovery in the plant

MSWI MULHOUSE-FR

2006

For the Cabinet Merlin: expertise on disfunctions CO / NOx / Dioxins, analysis of the existing systems, testing and proposals for modification

MSVI BELFORT SERTRID-FR

2004

Expertise bilan de fin de réalisation d'une usine d'incinération neuve de 2 lignes.

Étude des réclamations, propositions d’accords entre le maître d’ouvrage et les fournisseurs.

Étude des réclamations, propositions d’accords entre le maître d’ouvrage et les fournisseurs.

MSWI LIMOGES STVL- ONYX -FR

2003

Expertise of dysfunctions and proposals for solutions including compliance to 2005 standard

MSWI OF MANS-FR

2003

Expertise dysfunctions of the new flue gas treatment

Resolutions proposal

Resolutions proposal

MSWI MONTBELIARD-FR

2003

Site expertise

Proposals for optimization of capacity and technical tests

Results: Increased Capacity> 10%

Proposals for optimization of capacity and technical tests

Results: Increased Capacity> 10%

VITRY HABITAT-FR

2003

Combustion and control system expertise

Tests on the 5.5 MW boiler: reduction of CO by a factor of 5

Proposals for implementation and renovation

Tests on the 5.5 MW boiler: reduction of CO by a factor of 5

Proposals for implementation and renovation

C&A COMPANY-FR

2003-2009

Expertise, advice, testing, legionella monitoring for group C & A (80 buildings)

Presentation of Legionella and its environmental consequences

Conducting a monitoring procedure (twice a year with relevant centers)

Monitoring: 2003-2009

Presentation of Legionella and its environmental consequences

Conducting a monitoring procedure (twice a year with relevant centers)

Monitoring: 2003-2009

CC LES TROIS SOLEILS RENNES-FR

DEPUIS 2003

Expertise and problem solving of air conditionning noise

Expertise and treatment of legionella problems within the sanitary hot water and the cooling systems

Tips and monitoring of changes:

- the previous systems

- the replacement of open evaporative cooling towers by closed air coolers

Expertise and treatment of legionella problems within the sanitary hot water and the cooling systems

Tips and monitoring of changes:

- the previous systems

- the replacement of open evaporative cooling towers by closed air coolers

©2016 - OPENELEMENT. TEMPLATE directed by SENSODE